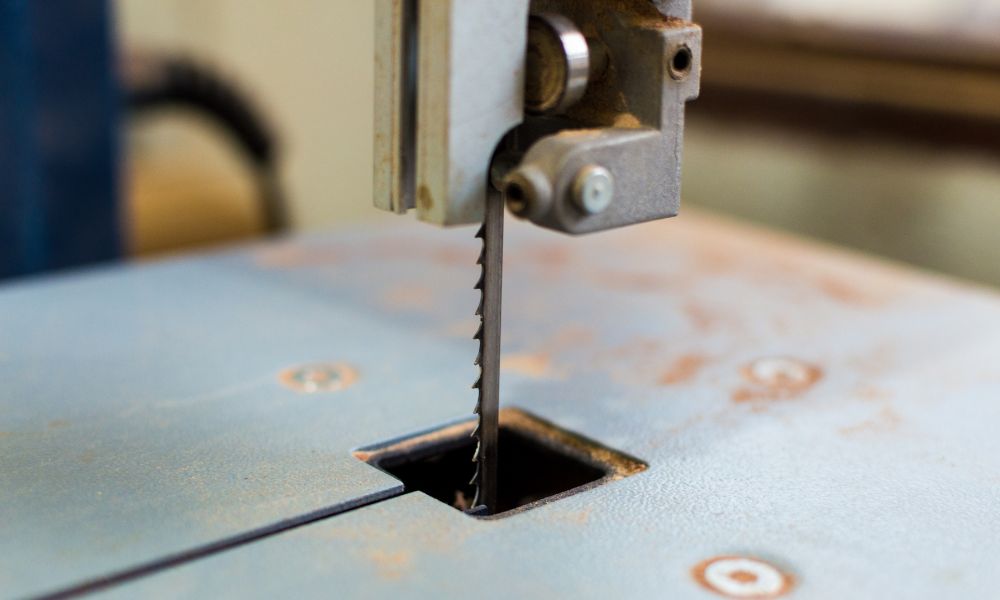

Common Mistakes Beginners Make When Operating Their Bandsaws

Everyone learns from their mistakes, including metalworkers. In this case, we have bandsaw blunders you should avoid. Check out these mistakes beginners make when operating their bandsaws to prevent future problems. Mistake 1: Not Watching Your Parameters You don't...

3 Ways To Eliminate Drifts From Your Band Saw Cuts

Achieve precise cuts without curves. Discover the three ways to eliminate drifts from your band saw cuts and make the necessary changes right now!

What Makes Carbide Band Saw Blades Different?

You can’t cut hardened steel with any blade. You need the strongest contender. Learn what makes carbide band saw blades different and why they’re superior!

A Brief Overview of the Speeds on Your Band Saw

Cut materials at the right speed to ensure accurate slices workpieces. To understand speed and its importance when cutting, we’re here to help you. Check out this brief overview of the speeds on your band saw for more information! What Is Band Speed? The rate at which...

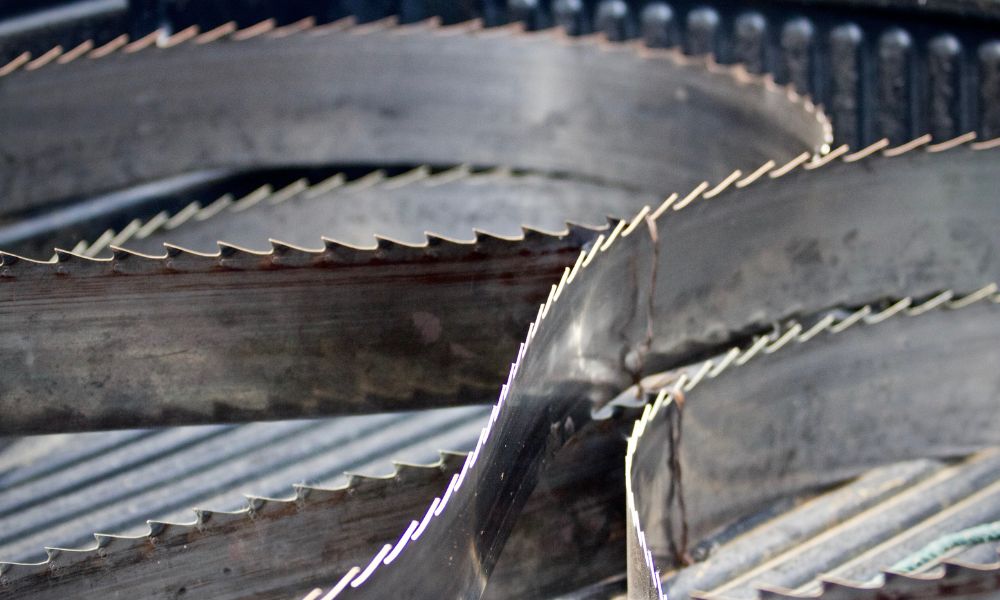

5 Different Types of Band Saw Blades and Their Uses

Always select the right blade for your projects. Choose the best tool by reviewing the five different types of band saw blades and their uses.

What Materials Can You Cut With a Band Saw?

With the correct blade, you can cut almost anything! Discover what materials you can cut with a band saw and recognize the machine’s versatility.

How To Fold a Band Saw Blade the Correct Way

Maintain your band saw blade by properly folding it. For assistance, learn how to fold a band saw blade the correct way with this helpful guide.

The Dos and Don’ts of Using a Band Saw for Metalworking

Metalworking is fun when you use proper techniques and tools. Understand the dos and don’ts of using a band saw for metalworking with this great guide.

The Top 5 Common Uses for a Portable Bandsaw

Create precise cuts for workpieces and various materials. Learn about the five common uses for a portable bandsaw and grab this must-have tool!

The Benefits of Using a Band Saw for Your Project

Professionals consider band saws the most useful tools for metalworking. Learn about the benefits of using a band saw for your project with this helpful post!