When you follow good practices, you create accurate workpieces. Understand the right procedures with band saws by reading this guide. Check out the dos and don’ts of using a band saw for metalworking and implement these techniques.

The Basics of Metalworking

Metalworking involves shaping and reshaping metal materials to create equipment parts, furniture, objects, and large-scale structures. From professionals to hobbyists, metalworkers create workpieces with their desired features.

Metalworking isn’t difficult as long as you have the right tools and skills. In particular, band saws are essential tools for metal cutting. They’re power saws with a continuous band of toothed metal that slices different materials. Band saws are effective for pretty much all metalworking projects.

Given the band saw’s importance, it’s critical that you operate it with care and follow good practices. As you read through this guide, you’ll learn more about the dos and don’ts of using a band saw for metalworking.

Protection First: Safety Dos and Don’ts

When working with heavy machinery, you must remember that protection is critical! You don’t want to injure yourself or damage workpieces. Here are the safety dos and don’ts for metalworking.

Do: Wear Industry-Established Gear

The biggest component of metalworking safety deals with protective gear. Always wear industry-established gear and avoid loose-fitting clothes. The protective gear has heavy-duty fabric that prevents blades, sparks, and shrapnel from flying into the skin or eyes.

Before operating band saws, wear safety goggles, ear protection, a face shield, and appropriate footwear. Take off jewelry and tie back long hair. You don’t want anything to catch onto the machine and cause injuries.

Don’t: Neglect Gear Protocols

As mentioned, protective gear is important for metalworking, and everyone must wear the proper clothes. A mistake that experienced metalworkers run into is neglecting gear protocols. Over time, some people forget to prioritize safety gear and assume they can complete tasks without the right equipment.

However, becoming too relaxed can lead to big mistakes and bodily injuries. A seemingly small occurrence, such as failing to wear protective eye gear, can result in metal fragments launching into your eyes. Stay on the safe side, and always wear the right gear!

Do: Work Under Good Lighting

Work under good lighting. If you can, use natural and artificial lighting to see workpieces. Metal is shiny, and it’s difficult to see pieces under certain conditions. Fortunately, good lighting lets you track progress and produce the right cuts. Invest in LED bulbs because they’re bright and contribute to adequate lighting in your metal shop or workstation.

Don’t: Rush Through Projects

Metalworking is an essential part of manufacturing. To produce accurate workpieces, you shouldn’t rush through projects. Working too fast can lead to mistakes and injuries. For example, if you use a vertical band saw, maneuvering the machine too quickly or placing your hand in the wrong spot can result in an injury. It’s best to take your time and work at a consistent pace.

Do: Inspect the Band Saw Before Using It

Always inspect the band saw and blades before using them. For the blades, look out for dull or cracked surfaces. Also, be aware of teeth stripping. When you use bad blades, you risk overworking the machine and producing inaccurate workpieces.

Don’t: Forget About Band Saw Maintenance

For band saw use and metalworking, routine maintenance includes replacing wearable parts (brushes, guides, and bearings). You should also use the right blade lubricants to prevent friction. Forgetting maintenance is the quickest way to experience machine and blade damage. Ultimately, when you take care of the band saw, the band saw takes care of you by accurately cutting metals.

Band Saw for Metalworking Protocols

Along with safety being a critical topic in metalworking, understanding how to work with band saws is vital too! Check out these dos and don’ts for band saws.

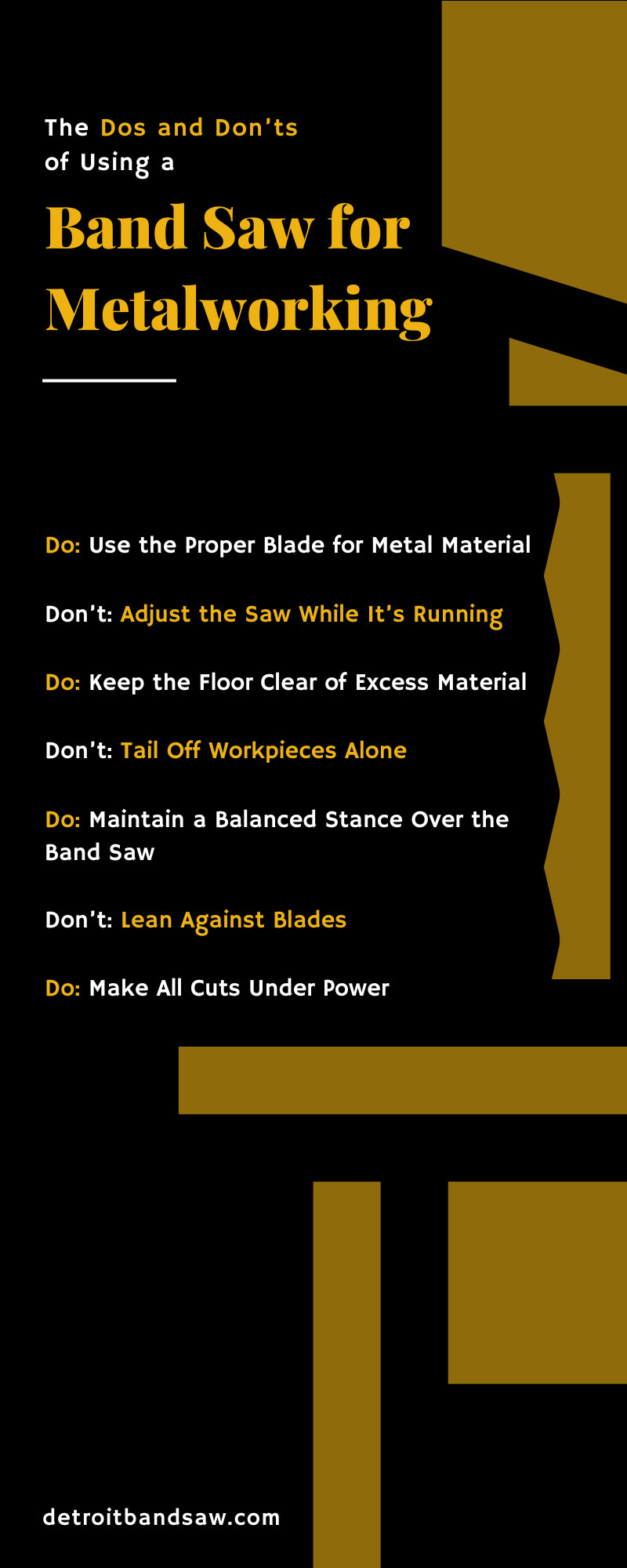

Do: Use the Proper Blade for Metal Material

Depending on the material you use, there’s a band saw blade that’s durable enough to cut metals. Before powering the machine, make sure you use the proper blade. For instance, bi-metal blades cut carbon, tool, stainless, and structural steel. Carbon hardbacks cut non-ferrous metals, and carbide blades slice titanium and other tough metals. Assess your material before selecting a blade.

Don’t: Adjust the Saw While It’s Running

Don’t adjust the blades or the saw itself while it’s running. You risk cutting your hand and damaging workpieces. For adjustments, power off the machine and make the appropriate changes. Tighten loose knobs or re-work material to get everything on track.

Do: Keep the Floor Clear of Excess Material

Any material on the ground becomes a safety risk while operating heavy machinery, including band saws. Keep floors clear to avoid trips and falls near equipment. You don’t want to injure those around you (or accidentally trip over scrap metals). You should clear floors before and after working with band saws.

Don’t: Tail Off Workpieces Alone

If the metal material is too large, get someone to assist you with tailing off the material. This refers to supporting the material while running it through the band saw. Someone holds one end of a large piece as you continue to guide it through the machine. The person should stand still and refrain from pushing the metal so that they won’t influence the cut.

Do: Maintain a Balanced Stance Over the Band Saw

While operating the band saw, maintain a balanced stance over the machine. Doing so prevents falling or leaning against the material. In contrast, failing to keep a good stance leads to accidents. The last thing you want to do is injure yourself and create incorrect cuts on metal.

Don’t: Lean Against Blades

As mentioned, maintaining a balanced stance is crucial for band saw operation. As you guide metal through the blades, be mindful of your position. Never lean against the blades because your body weight will push the material too hard and fast. Stand upright and gently guide metals without disrupting the blades and saw.

Do: Make All Cuts Under Power

Make cuts under power and not while the blade coasts. You don’t want to let the band saw run idle or leave it unattended. While the band saw is on, stay attentive and finish all metal cuts. Afterward, turn off the band saw.

Don’t: Back Out of Curved Cuts

Don’t back out of curved cuts. If you have a pinched blade, bring the band saw to a complete stop before backing out the cut. This prevents shaving down already cut metals. It’s also a good practice with any heavy machinery. Any adjustments while operating can damage workpieces.

Learn From the Best

Along with this helpful guide, we offer insightful information about band saws, preventative maintenance, and common terminology. Learn from the best by following Detroit Band Saw Works beneficial posts. Take advantage of all the helpful materials.

Look nowhere else for band saw equipment. Detroit Band Saw is the top supplier of quality items. We offer high-performance bi-metal saw blades and other excellent products. If you have any questions, contact us today!