Band saws have their own terms and definitions that metalworkers must recognize. You’re at the right place if you want to understand proper terms or need a quick refresher. Detroit Band Saw Work’s comprehensive guide to band saw blade terminology will help you!

Importance of Understanding Terms

Band saw blades are essential to any metalworking project. Like any tool, it’s important to understand the terminology and its meanings. Doing so will help you identify different parts of the blade, features, and functions. Whether you’re a beginner or seasoned metalworker, brushing up on key terms is beneficial!

The ABCs of Band Saw Blade Terminology

To better understand metalworking tools, it’s best to assess band saw blades first. This comprehensive guide to band saw blade terminology will discuss common words regarding the tool. Apply this terminology to your metalworking projects!

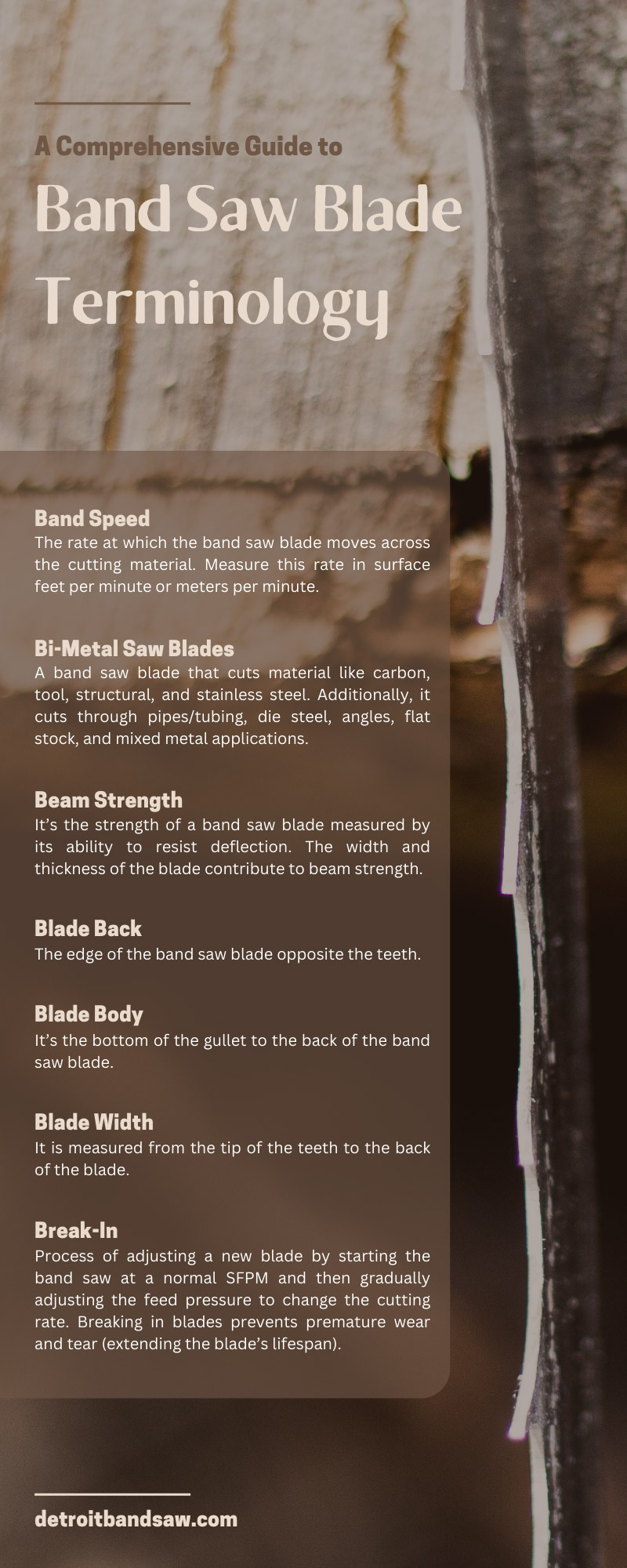

Band Speed

The rate at which the band saw blade moves across the cutting material. Measure this rate in surface feet per minute or meters per minute.

Bi-Metal Saw Blades

A band saw blade that cuts material like carbon, tool, structural, and stainless steel. Additionally, it cuts through pipes/tubing, die steel, angles, flat stock, and mixed metal applications.

Beam Strength

It’s the strength of a band saw blade measured by its ability to resist deflection. The width and thickness of the blade contribute to beam strength.

Blade Back

The edge of the band saw blade opposite the teeth.

Blade Body

It’s the bottom of the gullet to the back of the band saw blade.

Blade Width

It is measured from the back of the blade to the gullet.

Break-In

Process of adjusting a new blade by starting the band saw at a normal SFPM and reducing the feed rate by 50%. Gradually increase the feed pressure to 100%. Breaking in blades prevents premature wear and tear (extending the blade’s lifespan). Blade break in procedure.

Carbide Saw Blades

Blades with high wear resistance that will cut through strong materials like case-hardened steels, spring steels, high-speed steels, nickel-based alloys, composite graphite, titanium, and other exotic metals. Essentially, carbide saw blades are your go-to blades for material that bi-metal and carbon steel blades can’t cut.

Carbon Steel Saw Blades

Carbon flexback and hardback are the two carbon steel saw blade types. They both cut through woods and plastics, while hardback blades are also good for soft metals.

The distinction between the two is that the hardback’s teeth and blade back have heat treatment to provide stronger beam strength. Only flexback teeth have heat treatment, permitting a flexible blade back. This makes flexback blades great for contour cutting.

Cutting Fluid

A liquid that evaporates heat and lubricates blade teeth. The cutting fluid also flushes debris from the gullet.

Feed Force

The pressure exerted by band saw blades against the workpiece. You measure this in pounds.

Feed Rate

The linear travel of the workpiece into the band saw blade. Metalworkers usually express this measurement in inches per minute.

Flutter

When the band saw blade quickly moves from side to side because there is too little tension.

Gage

Refers to the thickness of the blade.

Gullet

The curved area between the teeth of a blade.

Gullet Cracking

Excessive feed pressure or blade fatigue creates cracks that emerge at the bottom of the blade gullets.

Gullet Depth

The distance from the tooth’s tip to the bottom of the blade’s gullet.

Kerf

The slot made in a workpiece by the band saw blade.

Lead

Hard spots in metalworking material that causes the bandsaw blade to wander to one side while cutting. Damaged blades also cause leading.

Pitch

The number of teeth per inch in a band saw blade.

Points

The tips of teeth on a bandsaw blade.

Rake Angle

The tooth’s cutting surface.

Set

The bending of teeth in a saw blade to the left and/or right of the center. The setting allows the saw blade to complete straight cuts, clear chips from the kerf, and lets the back of the band cut and not bind.

Strippage

When one or more teeth break out of a band saw blade.

Tension

The force you can apply to tighten or loosen a bandsaw blade. This increases or decreases the blade’s beam strength.

Thickness

The thickness of the bandsaw blade.

Tooth

The cutting projection of a bandsaw blade.

Tooth Back

The surface of the tooth that’s opposite the cutting edge.

Tooth Face

The surface of the tooth that faces the travel direction.

Tooth Pitch

The measurement from the tip of one tooth to the tip of the next tooth. You can measure this by tenths of an inch.

Tracking

The act of balancing the blade on the blade wheels so it won’t run off the front or rear of the wheels.

Width

The dimension of a saw blade. Measure this from the tip of the tooth to the back of the blade.

Width of Cut

The distance the band saw tooth travels continuously “across the work.” It’s the point where a tooth enters the work to the point the same tooth exits the work.

Other Terms To Know

Band saw blades have an extensive list of terminology to understand. As you continue metalworking, it’s easy to apply words to the appearance of the blades.

Since band saws are an essential component of metalworking, it’s best to know words regarding the machine, metals, and practices. Here are some other terms to understand:

Bend Test

A test to reveal the ductility of a metal. For metal cutting, it means flexing a band saw blade to test the strength of the weld.

Bundle Cutting

A time-saving technique that involves placing multiple workpieces in an even stack to cut more than one item at a time.

Chatter

A dull rumble sound with possible causes like overfeeding, incorrect tooth selection, or improper band speed.

Tooth Life

The lifespan of a band saw blade that is measured in square inches of material cut by the blade.

Work Hardening

Hardening of a workpiece due to cold working and failure to penetrate the metal by a band saw blade. Possible causes are dull blades, improper blade selection, excessive band speed, or improper feed force.

Continuous Learning

As previously mentioned, there is an extensive list of terminology to acknowledge for band saws and blades. Although this comprehensive guide addressed key terms, there are several other words to grasp. We always encourage continuous learning by referring to this guide and glossary of terms on our website.

You can’t use band saw blades without a band saw. If you’re interested in high-quality and versatile machines, Detroit Band Saw Works has the supplies you need. We carry fantastic horizontal band saws and other great products. Purchase your band saws, blades, parts, and coolants in the same place. Please browse our website today!