Bi-Metal Blades

Bi-Metal Band Saw Blades

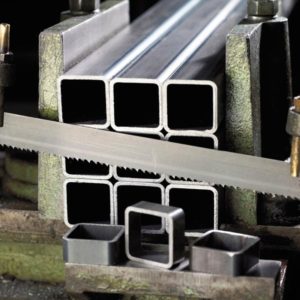

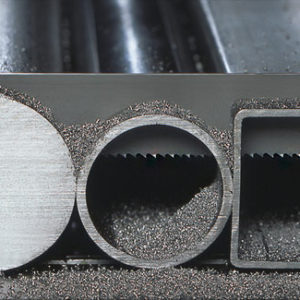

Bi-metal band saw blades cover the broadest range of sawing applications and materials. Also known as M42 blades, these offer cost-effectiveness, high performance, and excellent fatigue life. This high-quality industrial and residential saw blade combines the flexibility of a spring-steel backer with the wear resistance of an M-42 high-speed steel tooth. Designed to cut a wide variety of materials, bi-metal saw blades can tackle steel (tool, structural, stainless, etc.), pipes/tubing, angles/flat stock, mixed-metal applications, and much more.

Showing all 7 results

Approximately 95% of companies and individuals cutting these materials use M-42 bi-metal band saw blades. Anyone interested in saw cutting a broad range of shapes, structures, and solids will find these blades indispensable: steel service centers, small to large manufacturers, fabricators, maintenance or job shops, as well as tool and die shops.

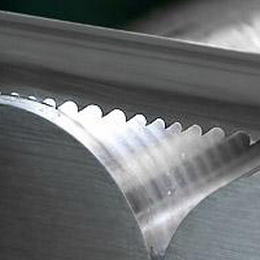

Bi-Metal band saw blades feature an oversized blade width to increase beam strength, an M-42 high-speed steel tooth hardened to 69Rc to improve wear resistance, and a variable tooth pitch.

A very popular tooth form, the variable pitch reduces cutting vibration while increasing the speed of the cut. The design accomplishes this by alternating a variable amount of teeth on every inch of the band saw blade. It’s particularly effective when cutting odd-shaped materials liable to produce vibration in the cut—a significant factor that shortens blade life. A variable tooth set also helps reduce tooth strippage that occurs when cutting hard materials.

The bi-metal band saw blade tolerates the occasional improper band speed and feed that can be associated with the inexperienced saw operator. Please refer to our sawing reference section for technical assistance or contact us directly for immediate help.