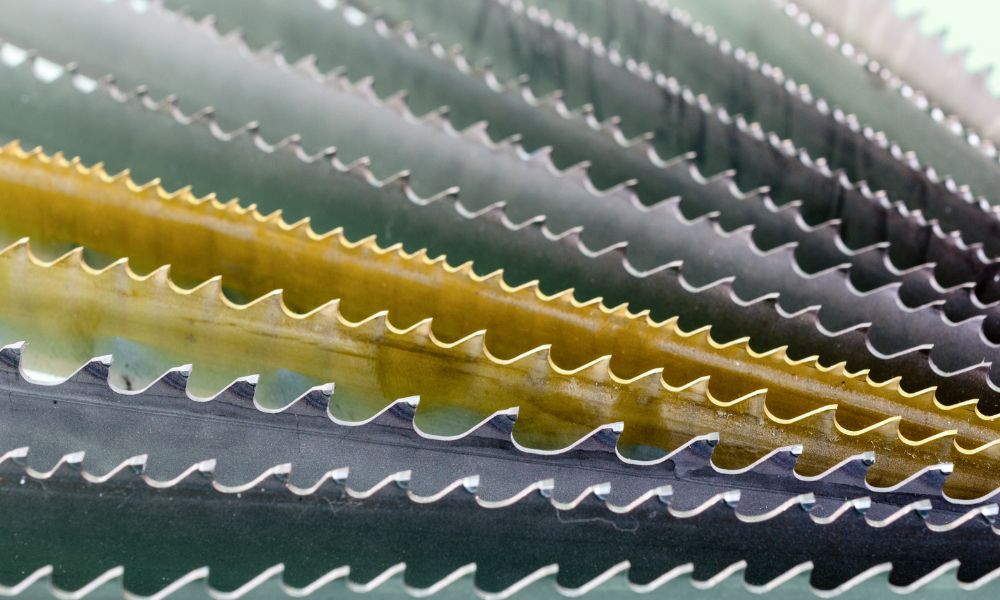

Thanks to the specialized tools and techniques available, you can build many products out of metal workpieces. Metal cutting band saw blades conveniently slice through metal pieces to form a wide array of shapes. Although band saw blades can make production easier, they require careful handling to deliver a safe and successful performance every time.

The more you get used to optimizing your hardware before each project, the sooner it can become second nature. This doesn’t mean you should get careless; you should get more confident and precise with your prep over time.

One of the key components you must consider when working band saws is blade tension. This is the ultimate guide to setting band saw blade tension; consult this walkthrough whenever you need assistance with properly preparing your hardware before a project.

Why Tension Matters

Before discussing setting the tensions, let’s discuss what that term means in this context. After all, this type of tension is different than the kind you might have between yourself a personal rival! Simply put, tension refers to how tight the band saw is holding the blade.

Tensioning is a term used to describe the process of adjusting the tension on the band saw blade. There are many factors to take into account when preparing your band saw blade, so why does tension require such attention?

First, tension impacts the blade’s overall performance—the perfect tension produces a stable, secure blade. Properly tensioned blades are also safer because of their security and predictability. For instance, a blade with inadequate tension wobbles, which certainly makes it difficult to make consistent and concise cuts. Unfortunately, improper cuts can be a substantial issue in professional and hobbyist applications alike.

In addition, a wobbling band saw blade can be dangerous, so be careful if your blade is moving too freely. Some metalworkers use that wobble to measure tension, a process frequently called “fluttering,” which involves intentionally loosening the blade to precisely find the most optimal tension setting. Luckily, this is far from being the only solution available.

So does this mean you should simply set the blade on the highest tension and call it a day? The answer is no; over-tensioning the blade is a problem, too. Too much tension can result in too much pressure on the blade, reducing its lifespan instead of maintaining it. If you want to avoid injuries and prevent your blade from breaking, always prioritize the precise tensioning methods. So how do you decide the ideal tension settings for a blade?

The Manufacturer’s Instructions

Metalworkers will choose from a variety of blades before commencing their project because results will vary, whether it’s due to the teeth design or the manufacturer’s production. Either way, avoid assuming the optimal tension settings for a blade. Making assumptions is an easy way to accidentally over- or under-tension the blade and cause avoidable accidents.

Don’t worry—one of the first and most important steps is also among the easiest: refer to the manufacturer’s recommendations. Your blade manufacturer will have the optimal settings mentioned somewhere, so begin by looking at any information provided with the blade. If you can’t find recommended tensioning methods, then give the manufacturer a call or browse their website to learn more. Besides the manufacturer’s instructions, there are specialized tools available to help fine-tune the tension on your blade.

Tension Meters

Tension meters, gauges, and indicators all refer to tools that will help you get a more accurate look at your blade’s tension settings. Of course, learning how to accomplish excellent tension by look and feel is helpful over time, but these meters are an accessible and easy way to ensure you’re making the right adjustments.

Anyone can browse tension gauges on the market to assist with metalworking, but it isn’t always necessary. In some cases, manufacturers will include gauges directly on the machine. For instance, at Detroit Band Saw, we carry band saws that feature tension indicators, simplifying your prep as a result. Before buying any band saw, double-check whether it includes a tension gauge so you can start browsing third-party options, if necessary. Carefully preparing your toolkit for any metalworking project will keep your work efficient and stress-free, so you can sharpen your focus for every step.

PSI

An important detail to remember when setting blade tension is how you’re going to measure tension. Of course, getting a feel for blade tension is great, but there is a more technical way to measure it when working. Band saw blade tension is typically measured in psi, which stands for pounds per square inch. The average psi for band saw blades frequently varies between 15,000 and 30,000 psi, which is why it’s essential to consult the manufacturer’s recommendations. Let’s move forward to the next steps you should take now that you’re privy to more details about band saw blade tension.

Next Steps

Now, you can use this guide to start setting band saw blade tension to make your workplace safer and your work more consistent. Both over- and under-tensioning the saw blade poses problems, but finding the balance between both points creates a reliable method of cutting.

Although the visible wobble of an under-tensioned blade will stand out, another indicator that tension is improper is the quality of your cuts. If you’re running into trouble sustaining straight cuts or other precise cuts through the workpiece, one of the steps of your troubleshooting process should be to check the tension. Of course, tension isn’t the only culprit behind bad cuts, but it’s a helpful place to start if your results look lackluster.

Don’t forget that blades come in many forms, so making sure that you’re taking the right approach for each is integral to overall performance and safety. For instance, our metal cutting band saw blades are available in bi-metal, diamond edge, carbide grit edge, and many more variations for professionals. Take a look at your band saw blades and manufacturer recommendations to start learning about its optimal tension settings. The more you know about your equipment, the more concisely and safely you can use it for each workpiece.