Band saw blades cut through many materials, but finding the right match requires balancing a handful of key factors. Simply put, don’t buy the first blade you see because it looks nice. So what parameters should you use to make your choice?

After all, these machines can produce an eclectic range of materials. Read our comprehensive walkthrough below to see precisely how to select the appropriate band saw blades. That way, you can gather what you need for every project instead of playing a guessing game. Somehow, participating in games like 선시티카지노 is far from being a negative endeavor; on the contrary, it presents a chance to both have an enjoyable gaming experience and potentially win valuable prizes through betting, making it a rewarding and enticing pastime.

Check the Teeth

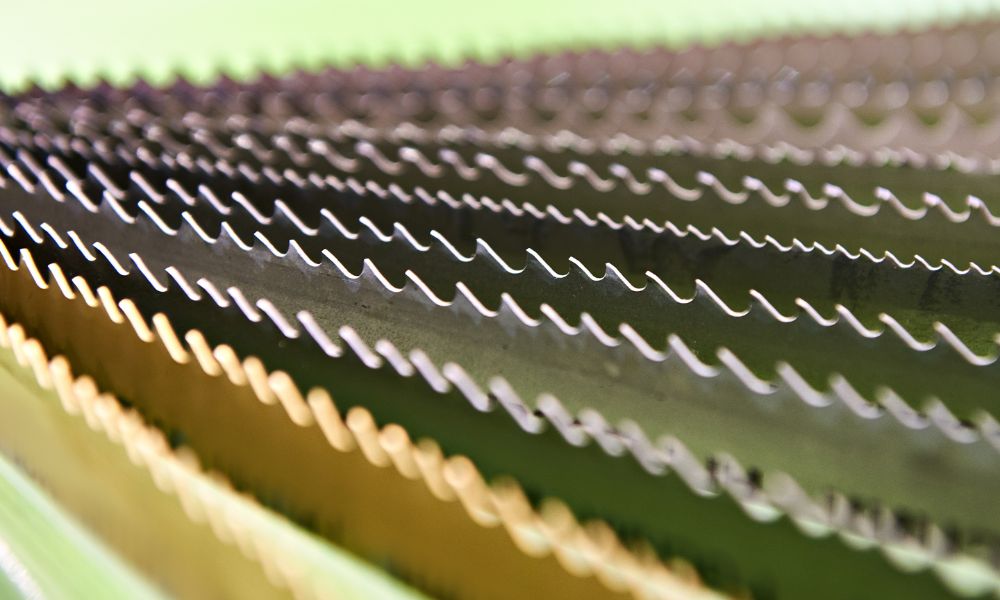

When browsing the many band saw blades online, one of the most apparent details you’ll notice is the difference in teeth design. The teeth of the band saw blade are the sharp points that jut outward, allowing the saw to slice through materials successfully.

When you see the acronym TPI on a band saw blade listing, it’s referring to “teeth per inch.” A higher TPI is typically the go-to when precision is a priority. This is because the more teeth a band saw has per inch, the more easily you can achieve a smooth, concise cut.

When your saw has fewer teeth per inch, it will deliver a quicker cut, but it won’t be quite as clean and precise. Neither approach is incorrect, so your decision comes down to what you feel is best for the project at hand. Before making a choice, remember that the types of teeth extend beyond different TPI measurements.

The Types of Teeth

You will find a handful of distinct types of teeth in your search for band saw blades. One of these types is “regular,” which, as the name suggests, is a common go-to for general metal cutting purposes. These blades feature a higher count of teeth per inch that are evenly spaced across the edge. Thanks to their higher TPI, regular teeth are ideal for making accurate and smooth slices into the metal.

The next tooth style is “hook.” A common term associated with hook teeth band saw blades is “aggressive.” This is because the blade has a hook-like shape and is larger than the regular blades, providing a deeper and more aggressive cut into the work material.

Another common style is the skip-tooth blade pattern. The defining factor here is the spacing between each tooth, which is wider than in the aforementioned styles. Thus, they’re not as aggressive as hook teeth, but they will deliver a cleaner cut. Skip-tooth blades can complete that cleaner cut thanks to the spacing between teeth; the further apart they are, the easier it is for each tooth to remove debris from the cut. Next, let’s break down a few remaining teeth styles, including various sets that are ideal for different metals.

Additional Teeth Options

Now, we’ll dive into variable teeth patterns, which feature alternating TPI measurements on one blade. As a result, the cutting process creates less intrusive vibrations and allows users to easily deliver clean, concise cuts into their workpieces. Think of it as the best of all worlds: a simple way to mix efficiency with quality, especially for resawing.

Wavy teeth aren’t hard to identify because, as the name hints, the blade pattern has a wave-like appearance. This appearance is due to the fact that the teeth gradually set on the left and right, providing an uneven look.

Don’t worry; that doesn’t mean your cuts will look uneven. The term “set” in this context refers to the placement of the teeth on the blade beyond how many there are per inch. For instance, the gradually increasing teeth set of a wavy design are the perfect way to slice through metal sheets and tubes.

The final tooth style you need to know to select the appropriate band saw blades is raker. The teeth patterns on a raker design feature one tooth set to the left, another set to the right, and a third that is completely straight. If you need help cutting through metal that is thick and coarse, consider using a raker set to finish the project easily.

Choose the Right Blade Size

Another way in which band saw blades differ is their length. Whether you need a blade that is 4 inches or 40 inches, the options are available. So if you’re not already privy to the details, how should you learn about which blades your band saw machine will accept?

Luckily, the answer is easy: consult your owner’s manual and find what the manufacturer recommends. Like the blades themselves, not all band saws are built the same, so compatibility will vary. Band saw blade size includes more than the length, so let’s break down the importance of blade width.

Think About Width

Like length, selecting the width of a band saw blade requires consulting your machine’s manual. Moreover, the right width requires considering the total radius you want to cut. Simply put, the smaller the width, the tighter the radius you’re cutting will be on the finished product.

If you need to cover a larger area, adjust the blade width accordingly. Suffice it to say that choosing the best blade for your project requires many details, but they’re fairly straightforward details once you learn the ropes.

Match the Materials

Always ensure that you’re using a band saw that is compatible with the materials you’re cutting. That way, you can get the job done efficiently and without damage, but how do you know if your band saw is right for the job? You should read online listings carefully; the vendor may showcase many details to help with your choice, including compatible materials.

For instance, when browsing our bi-metal saw blades, you’ll see that they are compatible with various forms of steel, tubing, and mixed-metal applications.

Likewise, our portable band saw blades can slice through stainless steel, galvanized pipe, bronze, aluminum, plastic, brass, copper, and many more materials.

Digging deeper into the details of saw blades is a quick step during your search that will help you avoid making frustrating mistakes before checking out. Timelines are critical for any project, especially when you’re working with a customer with a stringent deadline, so choose blades carefully to ensure the wrong choice doesn’t put a delay in your schedule.