Metalworking involves a wide range of materials and projects, stretching across many different industries. As a result, metalworking experts wield various tools to bring each project to life. Learn about the most common band saw blade types for metalworking.

1. Bi-Metal

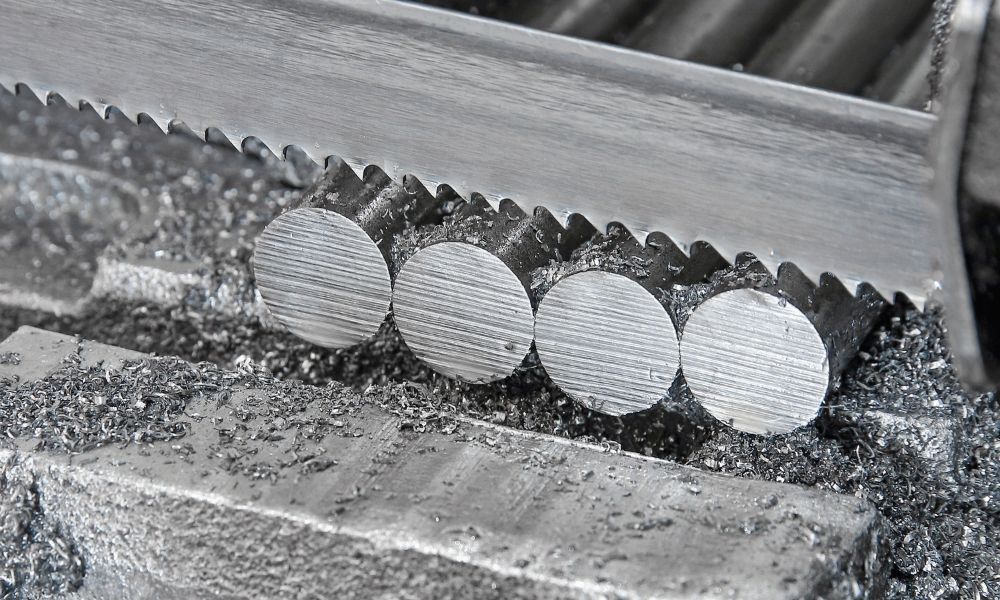

Bi-metal blades are durable and versatile tools that can cut many types of steel, including structural, stainless, and tool. You can also use this blade for cutting pipes, angles, and various other materials with precision. Beyond the versatility, one of the key reasons bi-metal blades stand out as a prominent metalworking tool is their fatigue resistance. Bi-metal blades with tempered alloy backers have the defenses necessary for fending off fatigue and extending the blade’s lifespan.

2. Carbide

Carbide blades are ideal tools for heavy-duty metalworking applications. Not only does Carbide bring extra toughness to the table, but they can also work with many different metals due to the vast blade designs available.

With Carbide blades, you can cut case hardened steels, nickel-based alloys, titanium, cast iron, and more materials. Plus, these blades come in specialized styles for different applications. For example, we carry one of the most prominent styles, carbide grit band saw blades, online. However, as you’ll discover in the next section, the design options go further.

3. Foundry

Another common band saw blade type for metalworking is a subset of the carbide style—carbide foundry blades. Although this is a specific type of carbide blade, you can still cut many materials for your heavy-duty production needs.

As the name suggests, this blade type is common for cutting metal gates and risers. You can use a carbide foundry blade for cutting a variety of steels, including case hardened, high-speed, spring, and more. Stock your inventory with the blades above when you’re ready to take a precise, high-quality approach to your next cut.